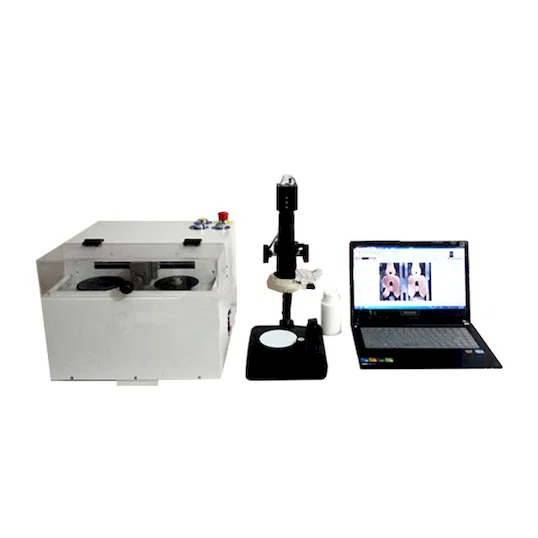

Mesin Uji Urutan Kabel Perumahan Baris Ganda, Mesin Uji Urutan Kabel Baris Ganda, Mesin Inspeksi

Urutan Kabel Baris Ganda Tegangan 200-240VAC 50 / 60HZ

Berat 20kg

Ukuran kemasan 560 * 440 * 450mm

Lingkungan kerja Suhu 0-40 °C, Kelembaban relatif < 80%

Uji warna Urutan kawat salah urutan, salah penempatan, PIN

Salah Uji kontinuitas 64PIN / sirkuit terbuka / Uji

Terbuka seketika Hasil uji siaran suara, kunci

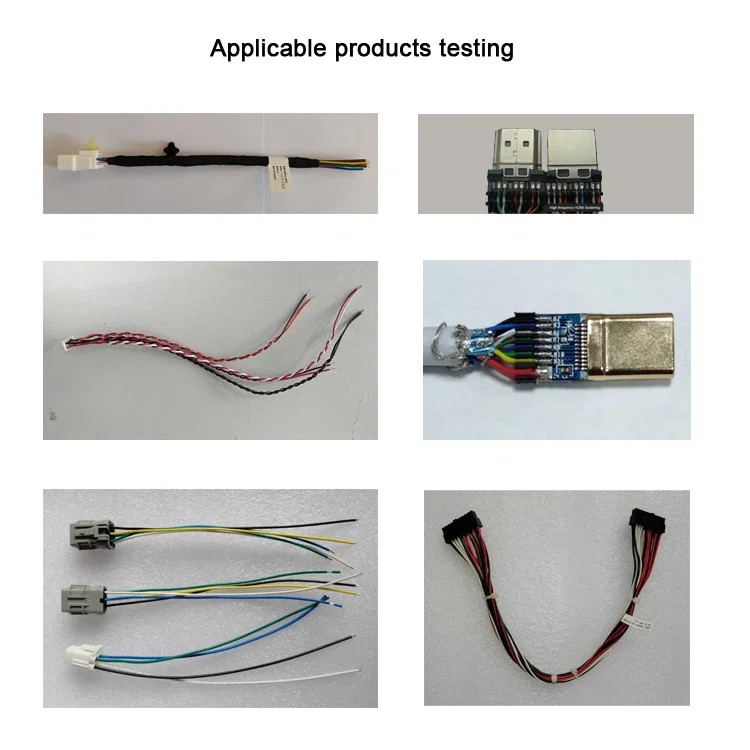

NG Produk yang berlaku Harness kawat otomotif, ujung tunggal 2 baris, 2 ujung 2 baris, Tipe-C, HDM1, USB, kawat-ke-PCB, penguji warna dan kontinuitas harness kawat 2 baris yang disesuaikan

Ada serangkaian penguji urutan harness kawat:

Fungsi tunggal, Baris tunggal / 2 baris, uji urutan kawat;

2-in-1, Baris tunggal / 2 baris, urutan kawat & uji kontinuitas;

3-in-1, Baris tunggal / 2 baris, urutan kawat & kontinuitas & cetak titik; Uji harness kawat komposit perumahan

Multi-ujung.

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek