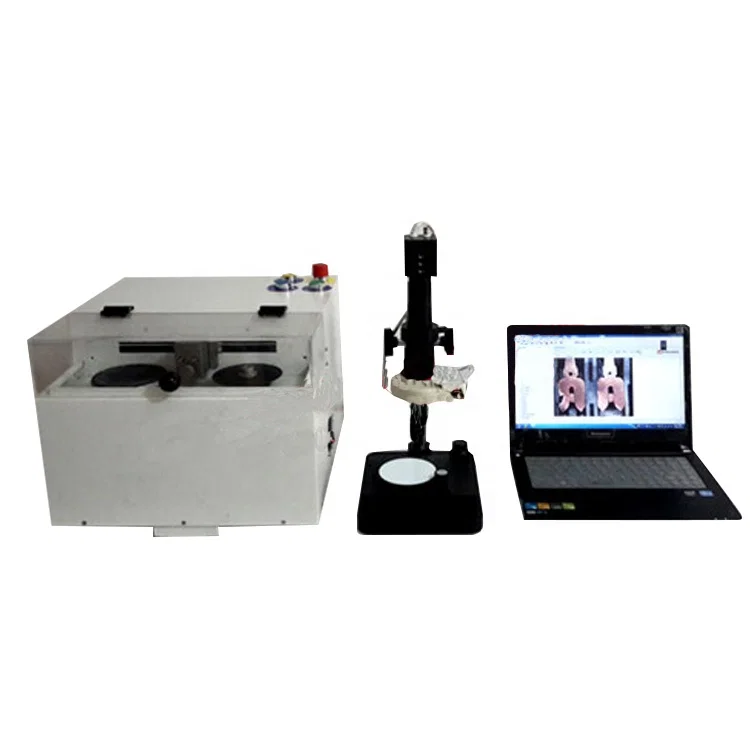

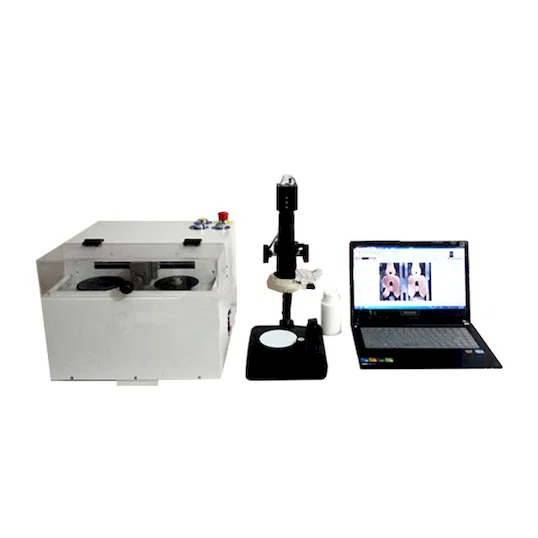

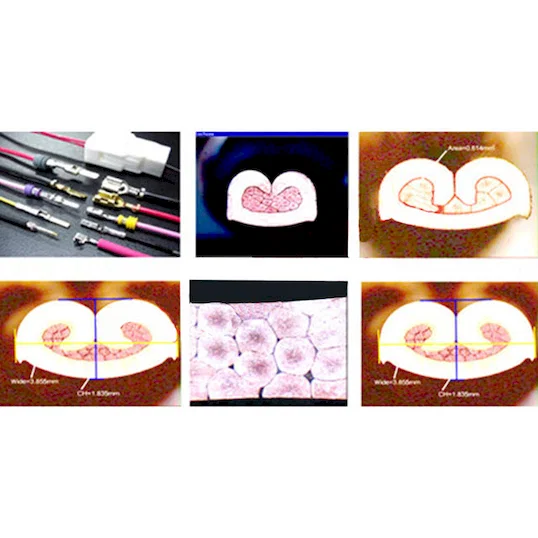

Sistem analisis penampang, penganalisis penampang harness portabel, mesin pengolah gambar penampang, penganalisis

Penampang kawat Analisis penampang yang diimpor Jepang Sistem

Optik zoom segmen kurang Pembesaran video Total Analisis bagian terminal Jepang mengimpor sistem

Optik zoom kurang segmen Pembesaran video total 30 ~ 312X

Rentang kawat yang berlaku 0,01 ~ 50mm2 Catu

Daya 100 ~ 240VAC, 50 / 60Hz

Sistem pencitraan Sistem video HD industri Jepang 5 juta

Spesifikasi pisau Dia.110X0.5mm (Jerman diimpor, halus dan tahan lama)

Amplas abrasif 1200 # Perlengkapan

Standar 0,01 ~ 50mm2

Penggaris referensi presisi tinggi kelas khusus 0,01 / 10mm

Korosi terminal Pembersihan cair (5S selesai)

Sumber pencahayaan Semua perangkat

Pencahayaan LED yang dapat disesuaikan putih Dimensi W500XD350XH350

W500XD350XH350

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek